This is an outdated version published on 2016-10-18. Read the most recent version.

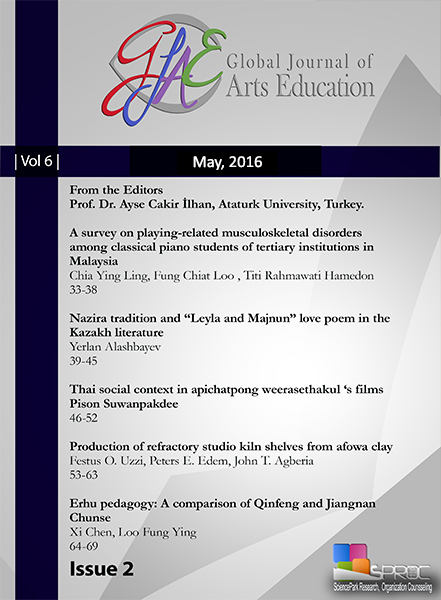

PRODUCTION OF REFRACTORY STUDIO KILN SHELVES FROM AFOWA CLAY

Main Article Content

Abstract

ABSTRACT

This study investigates production of refractory studio kiln shelves using Afowa clay. In solving firing problems, kiln was the earliest tool used to revolutionalize pottery productions, while shelves are among the furniture inside the kiln where ceramic green/bisque wares are stacked for firing. Most scholars in Nigeria who have written on kiln focused on construction of kiln, little has been done about kiln shelves production. Firing of pottery wares plays important roles in production of earthen or glaze wares. This paper deals with the production of shelves and suggests possible ways it can be used for stocking the kiln. It x-ray the problems associated with cracks on shelves and how to check them. The researcher also elaborates on different methods of propping shelves (bats) in stocking a kiln. Kiln setting for glaze firing follows a general principle of proper foot-cleaning and non-contact. The mechanical and physical properties of the composites are determined. Findings are made to show that there are improvement in hardness value, strength and compressive strength of the developed composites. Also, this research will impact positively on potters and institutions and will further open up research and creative development. It will hopefully discourage further importation of refractory materials and serves as reference material to potters.Â

Keywords: Production, studio, kiln, Firing and shelves.

Downloads

Download data is not yet available.

Article Details

How to Cite

PRODUCTION OF REFRACTORY STUDIO KILN SHELVES FROM AFOWA CLAY. (2016). Global Journal of Design Art and Education, 6(2), 53–63. https://doi.org/10.18844/gjae.v6i2.948

Issue

Section

Design and Arts

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

References

References

Akporhornor T. (2007) Ceramics and attendant Benefits: The other side of the Coin.

Being Text of a lead paper delivered at the National Conference of the Ceramics

Association of Nigeria, Deltal State University, Abraka.

Cardew M. (1956) “Pioneer Pottery at Abuja†in Nigeria magazine No52, pp38 – 49)

Echeta C. (2004) Glost Firing: Beyond thermosensors in CPAN journal of Ceramics No1

Nov. pp 14 - 19

Ewule, J. O. (1988) Development of Gas Kiln for Ceramics production from local

Resources: Master’s dissertation, A.B.U.

Hawkins J.M. (1996) The Oxford mini reference dictionary, New York: Oxford

University press, Walton Street.

Ibude I. (2012) Engineering Properties of Some Ceramic Local Raw Materials in Etsako

West Local Government Area of Edo State: Africa Education Indices 4 (1), 94-102

Ibude I. (2014) Chemical Analysis test on Auchi Black Clay and Afowa White Clay:

Creative minds and Productivity, 1(1), 1-9

Igwilo B. (1982) Firing a wood – Burning Kiln It economic valua in ceramic Art. In

Nigeria magazine No 140 pp11 – 28.

Lan Lauder (1976) The Home Potter, London: Barie & Jenkins ltd, 24 High bury

Crescent p.84.

Slawson, R. J. – Modern Kiln Furniture, Hanley: ACME marls ltd, stoke- on-Trent.

Uzzi, F. O. (2002) Conservation of energy: Design and Construction of kerosene

Dual Kiln, Master’s dissertation, Uniben.

Akporhornor T. (2007) Ceramics and attendant Benefits: The other side of the Coin.

Being Text of a lead paper delivered at the National Conference of the Ceramics

Association of Nigeria, Deltal State University, Abraka.

Cardew M. (1956) “Pioneer Pottery at Abuja†in Nigeria magazine No52, pp38 – 49)

Echeta C. (2004) Glost Firing: Beyond thermosensors in CPAN journal of Ceramics No1

Nov. pp 14 - 19

Ewule, J. O. (1988) Development of Gas Kiln for Ceramics production from local

Resources: Master’s dissertation, A.B.U.

Hawkins J.M. (1996) The Oxford mini reference dictionary, New York: Oxford

University press, Walton Street.

Ibude I. (2012) Engineering Properties of Some Ceramic Local Raw Materials in Etsako

West Local Government Area of Edo State: Africa Education Indices 4 (1), 94-102

Ibude I. (2014) Chemical Analysis test on Auchi Black Clay and Afowa White Clay:

Creative minds and Productivity, 1(1), 1-9

Igwilo B. (1982) Firing a wood – Burning Kiln It economic valua in ceramic Art. In

Nigeria magazine No 140 pp11 – 28.

Lan Lauder (1976) The Home Potter, London: Barie & Jenkins ltd, 24 High bury

Crescent p.84.

Slawson, R. J. – Modern Kiln Furniture, Hanley: ACME marls ltd, stoke- on-Trent.

Uzzi, F. O. (2002) Conservation of energy: Design and Construction of kerosene

Dual Kiln, Master’s dissertation, Uniben.